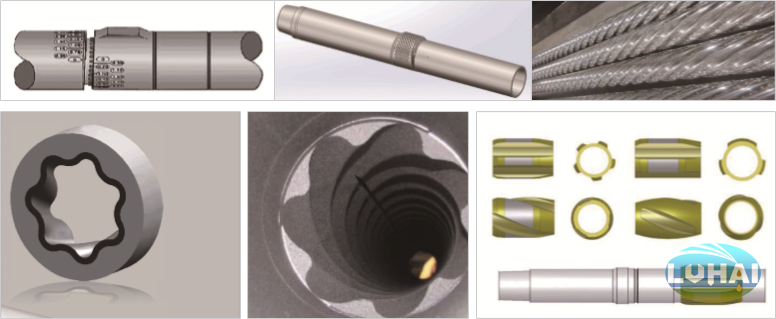

DeRun Energy drilling motor is a

positive displacement motor. High pressure drilling fluid flows into the

drilling motors, thereby enabling the hydraulic energy to be converted into

mechanical energy, at the same time, the rotor drives the shaft and bit to

rotate to achieve the purpose of drilling.

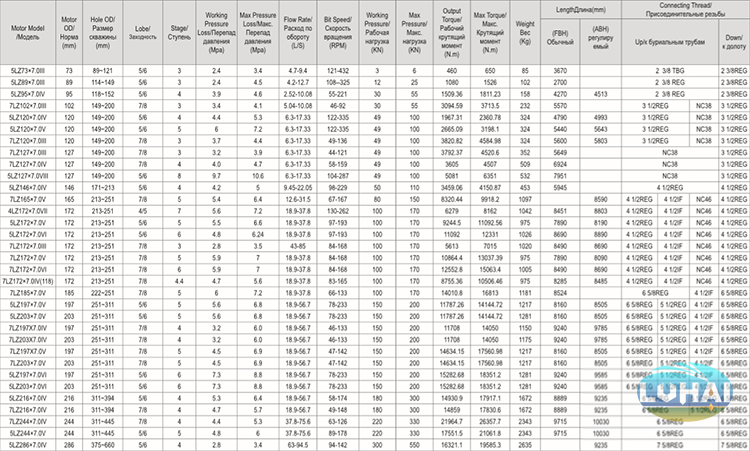

DeRun Energy produces LZ73, LZ89, LZ95,

LZ102, LZ120, LZ127, LZ146, LZ165, LZ172, LZ185, LZ197, LZ203, LZ216, LZ244,

LZ286 and other types of drilling motors. They are for drilling diameter of

88.9-660mm.DeRun Energy also design and develop drilling motors with special

sizes, different structural features and operating characteristics in

accordance with the user's requirements, thus forming different varieties. At

present, in addition to ordinary straight drilling motors, DeRun Energy can

also provide the following types of drilling motors:

Three types of top

sub connections

1.Bent drilling motors:

The bent angle on the universal shaft can meet different kickoff requirement,

there are single-bent and double-bent available.

2.Bent

angle adjustable drilling motors: The bent angle of the drilling

motors can be adjusted on well surface which enhance the extension of kicking

off.

3.Extension drilling motors: On

the basis of the ordinary drilling motor, improve motor torque to make the bit

drilling quickly by increasing motor stage.

4.Hollow

drilling motors: To meet the needs of high flow rate

solids carrying in drilling, hollow rotors with carbide nozzles of different

sizes are adopted, which can increase the input flow rate and the horsepower of

drill bit.

5.Drilling

motors with high kick-off rate: Unique structural design,

shorter body, bent point closer to the drill bit, and kick-off rate of up to >1°/m.

6.Saturated

saltwater mud-resistant drilling motors: To

maintain long time operation of drilling motors in saturated saltwater mud,

special rotor coating is adopted to provide better corrosion and wear

resistance.

7.High-temperature

drilling motors: In order to

improve the high temperature resistance of the stator rubber of the drilling

motors, to meet the drilling requirements in high geothermal gradient region

and deep and ultra-deep well drilling requirements, high-temperature resistant

rubber is adopted to increase the temperature resistance of motor above 150 ℃.

8.Sealed

driving shaft drilling motors: The

ordinary mud lubricated driving shaft is replaced with oil lubricated seal

driving shaft, which improves the working conditions of the thrust and radial

bearings, thus extending the service life of the drilling motors.

Features

& Advantages of Drilling Motors

1. Adjustable Bend Housing

In directional wells, horizontal wells,

highly-deviated wells and other special processes, adjustable bend housing

drilling motor adopts new universal shaft design to realize the adjustment of

19 different angles from 0 to 4° as well as overcome the shortcomings of

erodible exposed surface and short service life of the petal universal shaft.

2. High-Abrasion Housing

By using precision machining technology

and plasma surfacing technology to highly improve motor abrasion resistance

ability and stabilize motor kick-off rates.

3. Even Wall Drilling Motor

By changing the shape of the stator case

in a rational way, even wall drilling motor can help achieve thin and uniform

stator rubber layer to overcome the technical deficiencies in the stator of

conventional drilling motors. This type of drilling motor is characterized by

high thermal efficiency, sound thermal expansion and better sealing result. It

has wider application, more optimized structure and lighter body mass, which

help improve the working environment of drilling motors, thus prolonging the

service life.

4. High-Temperature Resistant Motor

High-temperature resistant motor adopts

the stator rubber made by special processes formula, to ensure the normal

operation at a high temperature of 150℃, which is suitable for high temperature

well and ultra-deep well drilling.

5.

Rotor Surface Treatment

Special chromium plating method can

control the ratio of the valley/peak chromium coating to 1:1.Tungsten carbide

coating of rotor can enable the rotor to work normally in saturated saltwater

mud, which successfully prevents the corrosion of chrome plated rotor by

saturated saltwater.

6.

Replaceable Sleeve Stabilizer

In order to meet the needs of different

drilling condition, different types of stabilizers is equipped on the housing

of the driving shaft: fixed and replaceable type available.

|